Along with the development of technology today, many pharmaceutical companies use ERP for pharmaceutical industry.

Today, more than ever, and with the pandemic still posing an imminent threat, pharmaceutical companies are facing more business challenges.

Competitive pressure, stringent regulatory requirements, radical healthcare reforms, and unpredictable market terrain are underpinning pharma manufacturers to the wall and forcing them to differentiate themselves.

Discerning consumers are now proactively demanding supreme-quality healthcare products at economical prices, which force companies to revisit their current operational practices and improve them. Pharmaceutical companies need to streamline their processes to stay competitive, maximize operational efficiency to reduce costs, and win consumer loyalty.

On top of that, they still need to uphold quality standards and precise regulatory compliance across all manufacturing processes, along with faster turnaround times.

Today’s customers are more informed, more vigilant, and more demanding, keeping players on their toes. It may be a long shot decades ago. Fortunately, today, it’s achievable if companies integrate an ERP solution with their system.

With ERP for pharmaceutical industry, pharma companies can respond to the challenges of a dynamic scenario and have a streamlined workflow, data-backed analytics, centralized management, and agile decision-making.

ERP for Pharmaceutical Industry

An ERP system is the command center of the company’s network. It controls, connects, and integrates all the autonomous aspects of a business may it be HR, planning, sales, marketing, purchasing, inventory, manufacturing, and business intelligence. A company can manage and control resources in real-time and save costs because of comprehensive visibility and transparency.

For an ERP to be truly advantageous, companies need to find suitable modules to elevate the management workflow. Here are the must-have ERP modules for pharmaceutical companies and the benefits they bring:

Global Integration

Most pharmaceutical products are usually produced by different companies worldwide, so the provisions for global integration is a must.

It should be able to handle conversions associated with barriers posed by differential time zones, currencies, language, etc. which could be taxing and time-consuming if manually converted and translated. Such is an excellent module to consider and must be in real-time.

Recipe Management

Pharmaceutical process manufacturing is complex. Since medications are very critical in one’s health, the chemical composition that is protected by copyrights should be fixed and accurately followed, not allowing a margin of error.

Choosing a pharma ERP that can do this is crucial since companies can formulate ingredients that are cost-effective and efficacious to stay afloat in the price war. It should integrate a tamper-proof database of raw materials, consumption, recipes, and compositions.

Inventory Management

Since the pharma industry is highly reliant on raw materials and compounds, pharmaceutical companies need to ensure that inventory is always sufficient and enough to meet demand and forecasts.

Inventory management modules allow managers to monitor and control pilferage in real-time. Decision-makers can also choose to configure the module to create triggers for needed replenishment and procurement, materials usage, and inventory status changes.

Security

Pharmaceutical companies spend a significant amount of resources on research and development initiatives.

It takes years of development and testing to get the right formulations, and when they do, they protect intellectual property through copyrights, which means that they do not want anyone stealing their formula.

Security breaches could be fatal for pharma companies, so an ERP system with stringent security protocols is a must.

CRM

Pharmaceutical companies need to have a centralized communication system where data of suppliers of raw materials and other manufacturing components are stored.

Users can save email, mobile numbers, fax, and other communication channels in the ERP with this CRM feature.

It is imperative when employees need to retrieve accurate data and information about the products and services they provide to customers.

A speedy traversal of messages across intended channels is pivotal in completing specific orders and maintaining good customer relationships.

Regulatory Compliance

The pharmaceutical industry should always be on top of the latest government announcements and industry news and developments from reputable medical groups.

To keep abreast of medical standards, compliance policies, and the latest distribution information, companies with ERP systems need to have this module to manage comprehensive compliance amid dynamic changes in the regulatory landscape.

Compliance managers can set configurations that notify and validate internal protocol and initiates check and balance within the system. The ERP system can ensure that the company performs vigilant audits and that it fully complies with regulatory mandates.

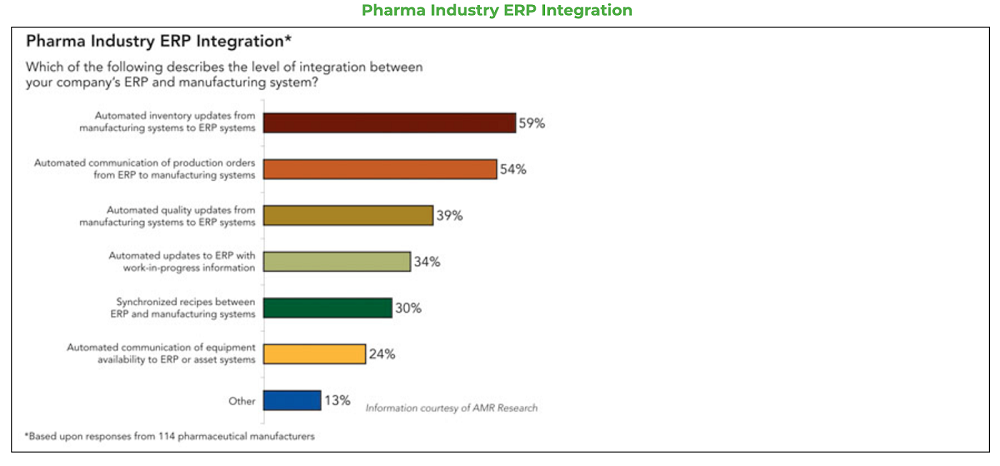

Fig 1. Pharma Industry ERP Integration, AMR survey of 114 pharmaceutical manufacturers

With the increased pressure on pharmaceutical companies, ERP adoption is a must.

But to realize its full potential, pharmaceutical companies must fully integrate ERP with plant systems such as Quality Management Systems (QMS), manufacturing execution systems (MES), as well as other software connecting RFID.

If you’re wondering if you need to deeply integrate ERP into your system, the answer is definitely because a tighter connection between ERP and plant-floor systems yield a lot of benefits. It paves the way for companies to realize all the benefits stated above.

Even if an ERP system is in place, companies cannot tap its full automation capabilities. Some companies have very loose plant and ERP integration that managers must still manually enter data. When you have such a disparate system, it’s quite a challenge to draw accurate information.

Fortunately, it gets easier when software vendors and integrators such as Syncoria are taking all the necessary steps to ease the challenges involved in bringing disparate systems and software packages together.

Quality improvement, cost containment, and visibility to inventory drive investment for integration in plant floor systems. With such integration applied, companies will realize the full potential of the ERP systems, allowing flexibility, sustainability, customization and scalability for future changes and expansion.