Controlling Machine Runtime and Downtime. It doesn’t matter if it is a bottleneck occurring right in the middle of your production lines. It doesn’t matter if it is a delay in your supply chain when things go awry. It doesn’t matter if it is the oodles and oodles of time spent trying to process returns and refunds, or fixing any sort of defect that arises over the course of your operations. For all companies, regardless of what industry they work in or what product or service they manufacture, time is money.

Therefore, downtime is the stuff of every production manager’s nightmares. Because every second your systems are down means precious time and resources are going to waste on things that should have been working in the first place.

Making a list of all the different ways your company could be wasting time and resources is a daunting, oftentimes time-consuming process, and there will certainly be problems that will cost even more of those resources to identify and fix from the source. For many small to medium-sized enterprises who have never had the experience of leveraging an enterprise resource planning (ERP) system like Odoo, it’s nearly impossible to determine where you even begin or what types of downtime are hurting your organization the most, much less which challenges to address first.

Here’s the good news, however – you don’t have to be whistling in the dark when it comes to addressing downtime and managing machine runtime when you and your employees are on the shop floor. Odoo ERP can help your business discern and determine what kinds of downtime are setting your business back.

Before anything else, however, we will need to determine what exactly machine runtime and downtime mean in order for us to see how Odoo can help control them – before they grind down your operations to a complete and total halt. Learn thoroughly how to controlling machine Runtime and Downtime well.

What is Machine Runtime and Downtime?

A period of time when a machine is not working is called downtime. When it comes to digital technology, the term describes a state when the system is offline and shut down. It can occur when the infrastructure is under repair, uninstalled, or is being replaced with another one. Runtime, on the other hand, is the opposite. It is a state when operations are running as they should be and the production line is flowing accordingly. So, controlling machine Runtime and Downtime is important.

Enterprise Resource Planning

The first thing to controlling machine Runtime and Downtime. An Enterprise Resource Planning (ERP) software is a centralized database system that stores, analyzes, and manages all the data that is connected to a business. The ERP systems are great for creating strong interdepartmental connections and motivates vendors and distributors to collaborate with each other. Originally, ERP systems were on-site frameworks that cost a lot of money and took ages to set up. Now, however, there are also cloud-based ERP solutions that bring more benefits and are much more cost-effective. And for mass production saved time literally translated to increased profits.

Controlling Machine Runtime and Downtime with an ERP

An optimal purpose of a factory or an assembly line is to guarantee as much runtime as possible and as little downtime as possible during the manufacturing process. To reach this goal, it’s important to reduce the flaws of the process, so that there’s nothing that triggers the shutdown and thus increases downtime. Various ERP modules and features can help a business achieve greater efficiency in the manufacturing process. Let’s take a look at several ways you can minimize downtime and maximize runtime.

Centralized database

What makes ERP systems great is that it creates a pool of information and then distributes the necessary date to different modules. If a company chooses to keep track of asset information by entering data manually, the maintenance cost can get very high. Analyzing and creating reports can be quite difficult too since it is a method that leads to more errors. But ERP systems can store huge amounts of data in a very efficient way. When a problem occurs, it will sort the information and find out what was the reason for it.

Optimal decision making

When you opt for manual data entry, you have to constantly refer to address books and manuals to get to the root of the problem. Naturally, that leads to even more downtime. With a centralized system, some standardized maintenance practices will be carried out while the professionals will analyze the maintenance history to find out where it went wrong.

Faster communication

Companies waste lots of time trying to get in touch with tech support. That’s why it’s really important to have fast and efficient communication with maintenance. ERP software like Odoo is connected to several devices that will notify the technicians of the disruptions of the supply chain. The notifications may either be sent out automatically or by any user who is still online within the mainframe. Communication is very influential in controlling machine runtime and downtime.

Proper inventory tracking

When it comes to repairs, inventory tracking is key. The necessary parts should be at hand as soon as possible, just like the tools that are required for fixing them. ERP systems can track these items to their location and determine where they were originally supposed to be. Inventory systems are also continuously kept up to date, so if some assembly part is low in stock, the vendor will be notified straight away.

Reporting features

People tend to forget the exact series of events that is necessary for the detailed reports. Besides, if the files are corrupted, outlining reports can get even more complicated. The processes in ERP are more complex, so they are much more precise in their reports. You can arrange preventive schedules and have frequent checkups to make sure a solution can be found automatically.

Accountability

Again, people usually get confused and forgetful when it comes to tracing an exact timeline of events. That’s why it can be very hard to determine at what point there was a systematic breakdown. With ERP software, everyone’s always on the same page, and all the activity is traced back to the projects. With such a hands-on approach, employees feel more responsibility for their projects

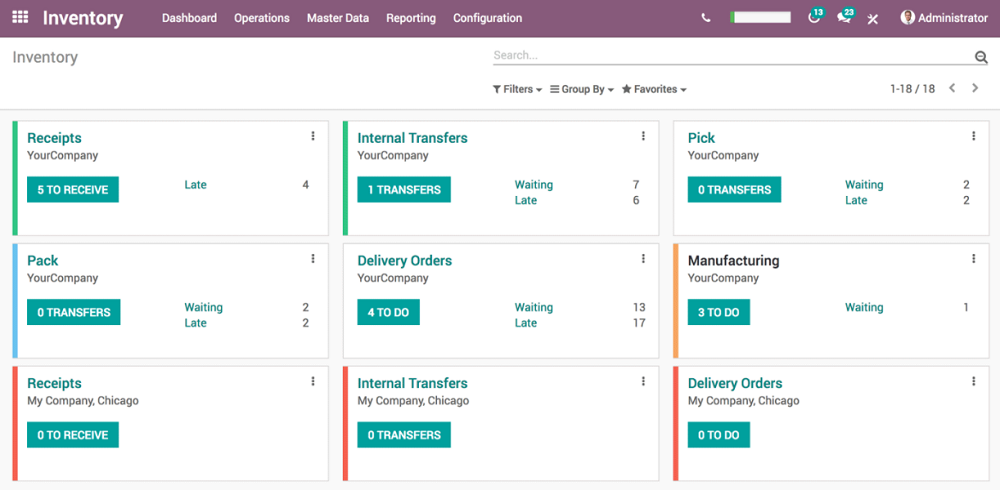

Now you know how various features of ERP systems help control runtime and downtime by automating many time-consuming processes, thoroughly studying every issue, and putting all the information together. While there are many different ERP systems in the market, Odoo seems like the optimal premium choice. Odoo is a simple software that does all the jobs in just one app: streamlining operations, managing invoices, and improving sales. There are many different apps that include a customizable template for your software, so no matter what your needs are, they will be covered.

Reducing Downtime with Odoo ERP

Waste is by far the biggest problem of both manufacturers and distributors. It can be too much inventory and raw material, the time dedicated to the simple mechanic tasks or money invested into failed projects. Unfortunately, every minute and dollar you waste results in fewer customers and less profit.

Monitor your processes

To cut downtime you need to know where it happened. That’s why automatic trackers are essential for monitoring all your cycles and machines for downtime and runtime. Odoo ERP has the flexibility and scalability you need to automate the monitoring process by using trackers that detect downtime in real time and send notifications to the factory floor to share the precise location of the problem.

With cost reporting for machine downtime, businesses can also learn to make better decisions. Automated production monitoring optimizes overall equipment effectiveness and plant productivity as well as minimizing the machine downtime.

Improve Communication with Employees

It is crucial that your employees genuinely try to do their best, otherwise, important processes will go out of hand and decrease everyone’s productivity even further. Moreover, production line workers have an important perspective on machine performance and manufacturing procedures.

Managers should constantly communicate with the employees so they feel appreciated and, at the same time, more responsible for their work. Supervisors should take their time to explain the connection between downtime and profits. This way the employees can have a deeper understanding of the processes they are working on and see their manager as an authority that they can communicate with. Set monthly or quarterly goals for minimizing downtime and come up with incentives for the employees who reach them.

Odoo ERP has several features that encourage effective communication. Since it offers real-time data, businesses can achieve better accuracy and more smooth collaboration. Furthermore, Odoo optimizes the collaboration by using messaging and notification tools such as instant notifications and hashtags. Product lifecycle updates will be shared among the team members so that the operations are running without flaws and the customers can get an optimal product. Collaboration creates a more successful and motivated team. The better in controlling machine Runtime and Downtime, the success rate in doing business will increase.

Regular Maintenance

By controlling machine Runtime and Downtime can reduce risk in business. Not performing regular maintenance on shop floor machinery can be a very risky move. One unexpected breakdown can lead to major downtime outcomes and expenses. With regular maintenance, you can minimize machinery malfunctions, keep machines working for a longer time, and find out immediately when you should get an upgrade. So, once again controlling machine Runtime and Downtime is very much needed in a business

Odoo has all the tools, applications, and modules you need to perform machine and tool preventative maintenance (PM), as well as automated notices and alarms for PV so that the operators can optimize their machines’ performance. With Odoo it is easier to stay on track with your maintenance schedules, equipment performance, and statistical quality, thus making sure your production lines are working as efficiently as possible.

Are you a manufacturer looking to use ERP to reduce waste on your shop floor? Get in touch with Syncoria today! Our expert consultants come from all segments of industry from all parts of the world, so we understand both the software and the unique needs of your business very extremely. Contact us today if you want to know more information as to how Odoo can benefit your organization – we’d love to be partners with you in achieving your business and organizational goals.